12

2024

-

01

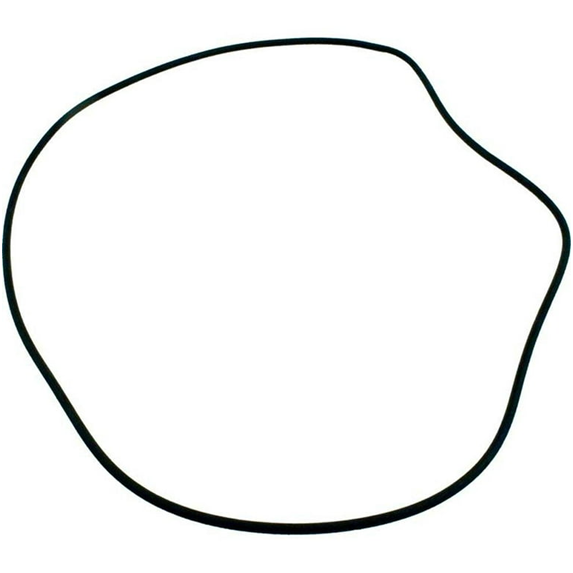

Custom-molded-o-rings

Compression Molded and Continuous Molded O-rings

Custom molded O-rings are recommended when non-standard size O-rings are required but do not fit well into standard AS568, common metric sizes, or are very large.

A full range of non-standard O-ring sizes can be customized by die-molding and continuous molding.

Compression-formed O-rings are suitable for both static and dynamic applications. Compression molding is preferred when a large number of small and non-standard sizes are required.Continuous molded O-rings are an excellent sealing choice for large, non-standard size dynamic applications. Our continuous molding process requires no tools and can handle almost any inner diameter. It is also the best choice for a small number of dynamic O-rings, which are not large enough to warrant cutting with a tool.

Continuous molded O-rings are available for dynamic and static applications as well as high pressure and vacuum environments. Continuous molded O-rings can be produced in a variety of material, hardness, bore and cross section combinations.

Comparison between custom O-ring technologies

The performance of continuous forming is similar to compression forming and is suitable for both static and dynamic applications. For the right amount of large diameter O-rings, continuous molding is the best choice because there is no mold cost. Compression molding requires molds, but is ideal when producing large numbers of O-rings. Vulcanized O-rings can be produced in a matter of hours, without tools, and are best suited for static conditions.

|

property |

Continuous |

Compression |

vulcanization |

|

Tensile strength |

excellent |

excellent |

good |

|

Delivery time |

2W |

4W |

Next day |

|

Tool cost |

without |

yes |

without |

|

Dynamic/static |

both |

both |

static |

Previous

Next

More News